四台格劳博五轴联动通用加工中心G750,一个可容纳120个800x800托盘的托盘存储系统,以及一座能够为四台加工中心提供刀具的中央刀库(可容纳870多把HSK-A100刀具)——这些主要特征来自于多贝玛亚(Doppelmayr)家族企业的一个互连系统。该系统用于生产由难加工材料制成的各种核心部件,以实现索道工程领域的大批量生产。

也许并没有多少人了解奥地利的沃尔福特(Wolfurt)这座小镇。位于此地的最大雇主——多贝玛亚拥有近130年的历史,是全球索道技术市场的领导者。相比于小镇而言,这座企业可能更广为人知。

对于一家传统的家族企业来说,质量、可靠、信誉以及安全等价值观深深植根于企业的经营理念之中。之所以如此,是因为作为索道工程制造商,多贝玛亚几乎只处理与安全相关的部件,其中所要确保的安全性在很大程度上取决于所使用的材料——由高回火锻钢制成的工件。“这种材料很难加工,”多贝玛亚机械生产部负责人Nicolay Schnitzer说到,“许多机床制造商都很难成功尝试。”

以恰当的时间带来正确的工件

多贝玛亚的项目经理NicolaySchnitzer开始寻找一个互连系统,来取代现有机械设备中的两台机床,以满足不断增长的产能需求。

大体来说,有几家制造商拿到了相关组件,以确定在设计和工时研究中做出最佳选择。“然而,我们的态度和发展历史都是相对传统的,”多贝玛亚生产部门经理Karl-Heinz Zündel在谈话中明确说道,“我们确实不想在生产中使用新的品牌。”

尽管如此,基本的一些问题仍然存在,比如谁能提供什么?谁拥有合适的主轴?谁的机床具有理想的动态性?以及谁可以为系统提供托盘交换器?工时研究的结果是明确的。虽然几乎每个供应商都能够为用于做出决定的参考工件提供最佳的特定加工时间,但格劳博的G750通用加工中心是迄今为止最具动态性的机床。它可以将工件加工时间缩短45%。

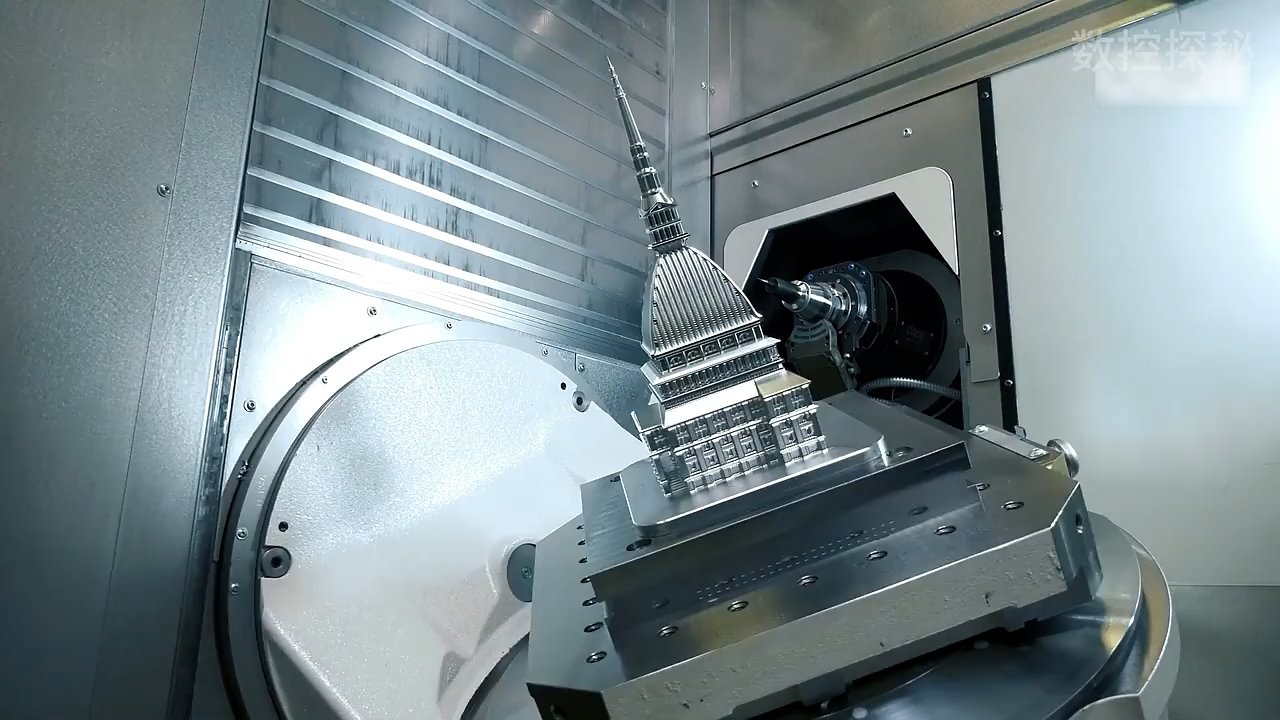

格劳博五轴联动通用加工中心 G750

令人信服的格劳博G750

Nicolay Schnitzer说道:“随着第二代G550五轴联动通用加工中心的投入使用,格劳博技术已经给我们留下了深刻的印象。”

工作台的运动学设计与卧式主轴相结合,使我们能够仅通过简单的冲洗和旋转循环,即可使托盘在加工后变得如此干净,以至于在托盘或工件上几乎找不到残余的切屑。这也使得冷却液的残留量降至最低。轻松的清洁过程节省了大量成本——对于单个托盘来说,这可能没什么大不了的,但是当一个周末过后,系统中有80个成品托盘,每个托盘只需要十分钟的清洁时间就可以重新用于加工,这些累计起来则可以节省很多时间和成本。

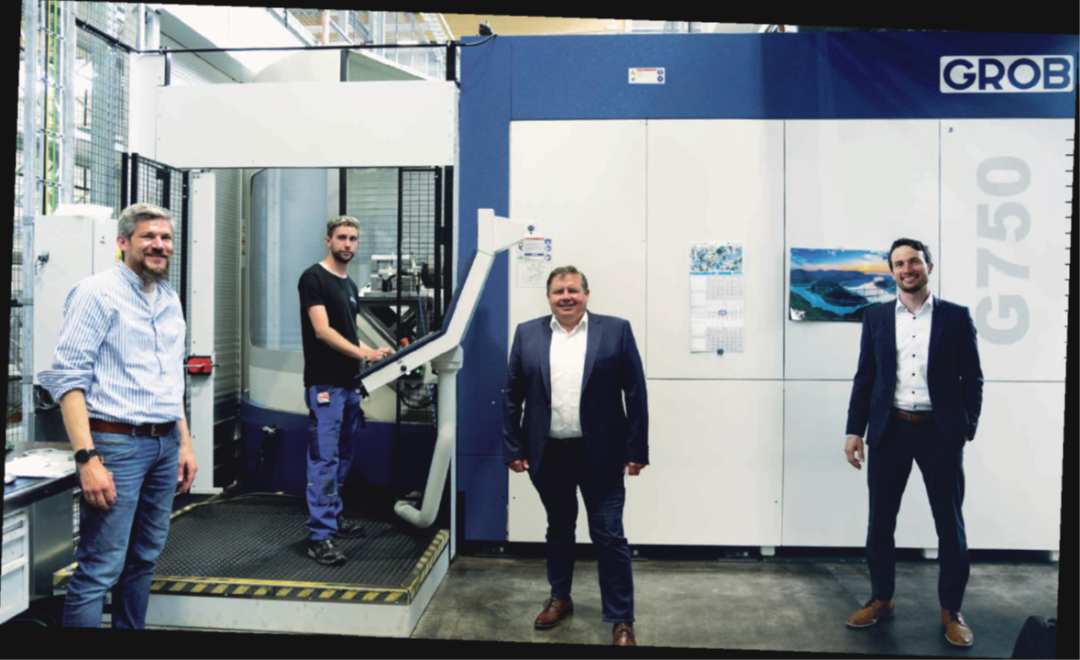

从左到右:多贝玛亚项目经理,Nicolay Schnitzer;多贝玛亚应用工程师,Dominik Sohler;格劳博在奥地利的代理 - Alfleth公司,Dietmar Hagspiel;格劳博区域销售经理,Christoph Demmeler。

多贝玛亚选择格劳博的另一个非常重要的原因是:G750的空间需求是所有候选机床中最小的。首先是因为机床配备了内置冷却液箱、排屑器和纸带过滤器,有助于缩短安装时间,安装空间非常紧凑;其次是,机床可以直接在工作区上料,这使得不需要在机床上安装额外的托盘交换器,这也意味着安装的空间需求更小。

独特的G模块设计使多贝玛亚能够实现多种夹紧方式,这需要旋转轴可以旋转到负角度的超大范围,这也是其他机床所无法做到的。“这一事实为我们提供了新的可能性来重新考虑夹紧方式和机床布局,”Schnitzer回忆道。多贝玛亚选择G750的另一个动机是:它可以从顶部装载,从而能够在自动化系统遭遇机器人故障时,仍能作为独立机床继续运行。

总而言之,格劳博五轴联动通用加工中心G750的具体优势是显而易见的。其最令人印象深刻的特征有:

- 高稳定性(面对加工材料带来的挑战,这一点很重要)

- 动态的运动学设计,可将参考工件的加工时间缩短40%以上

- 显著减少转换和重新装夹时间(由于减少了手动清洁的工作量)

- 无需托盘交换装置,可选择直接装载

托盘存储系统和中央刀库

通过自动化提高效率和生产率也是多贝玛亚生产中所关注的重要问题。因此,鉴于给定的结构条件,多贝玛亚的最终要求之一是:在一个外部托盘存储系统和一个中央刀库中,为120个托盘和大约870把刀具预留空间。G750较为轻松地解决了这两个决定性问题,因为格劳博机床可以安装在生产线中,并且可以在没有托盘交换器的情况下实现自动化。这不仅可以节省托盘交换器所需的费用,还可以对工作区域的合理进入方式保持不变,这对于处理新工件来说是一个关键点。

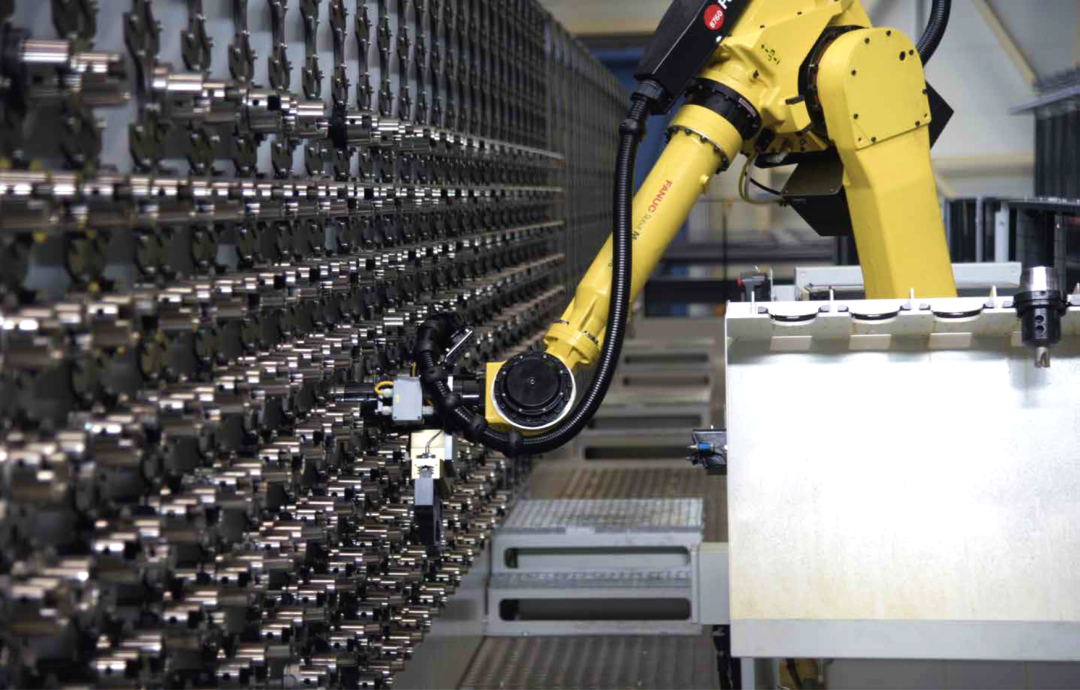

关于中央刀库方面,其所关注的主要是成本效益。四台G750通用加工中心各自都拥有一个带有60个刀位的换刀装置,但没有额外的外部刀具存储系统。Schnitzer说到:“就空间要求而言,在每台机床上都额外配有200个刀位的刀具存储系统是不现实的。”因此,该系统需要实现的功能是可以容纳870把刀具的中央刀具存储系统和用于运输刀具的机器人组合。由于每台机床都有自己的刀库,其中包含60把刀具,因此有共计约1110把刀具可用。龙门桁架系统可根据需要将刀具从中央刀库运送给相应机床。

可容纳870把HSK-A100刀具的中央刀库使得每个工件可以在任意机床中进行加工,为整个系统带来了极大的柔性。机器人额外配备了一个背袋,以实现更加快速的刀具装卸。

“具有先进设计理念和可靠服务的动态性机床成功将我们说服。在我们的互联系统中,冷却液和切屑残留完全可以忽略,这要归功于卧式主轴和旋转工作台。与Fastem系统的连接为我们提供了极大柔性。最后,该设计也是一个可以为我们最大程度节省空间的解决方案,让我们充分利用每一平米。”

Karl-Heinz Zündel

多贝玛亚生产和物流部门经理

“通过四台互连的G750,我们将参考工件的加工时间缩短了约45%,从而实现了成本效益的最大化。系统操作人员当然也将会非常乐意看到工件和夹具在清洁状态下从系统中出来。拥有120个托盘空间和中央刀库的完整系统为用户提供了卓越的灵活性,可在下一台可用机床上加工任意工件。该设计也因此带来了十分理想的布局!”

Dietmar Hagspiel

格劳博西奥地利销售部

多贝玛亚集团(Doppelmayr)

多贝玛亚集团在客运和货运索道工程以及高科技内部物流解决方案方面处于质量、技术和市场领先地位。

全球3403名员工

8.72亿欧元销售额

位于奥地利的沃尔福特

来自全球多贝玛亚/加拉文塔(Garaventa)的15100个系统

全球50个国家/地区设有子公司或公司集团办事处

可以在96个国家发现多贝玛亚/加拉文塔索道

格劳博五轴联动通用加工中心G750

加工铝制航空航天机翼框架视频

格劳博最新动态

English Edition

FOUR INTERLINKED G750 GROB MACHINES SQUARE THE CIRCLE

Four G750 GROB universal machining centers, one pallet storage system for 120 800 x 800 pallets and a central tool magazine with over 870 HSK-A100 tools to supply the four universal machining centers. These are the impressive features of an interlinked system belonging to the Doppelmayr family business for production of core components of various parts made of difficult-to-machine materials in very large quantities for ropeway engineering.

Not many know of the small town of Wolfurt, Bregenz in Vorarlberg, Austria. Its biggest employer, Doppelmayr, the almost 130-year-old world market leader for ropeway technologies, is probably more well-known to many more. A traditional family company for whom values like quality, reliability and trustworthiness, as well as safety, are firmly rooted in the company philosophy.

And that for good reason. As ropeway engineering manufacturers, Doppelmayr deals almost exclusively with safety-related components where the guarantee for the required safety is to a great part dependent on the materials used – parts made of highly-tempered, forged steel. "This material is difficult to machine, " says Nicolay Schnitzer, Mechanical Production Department Head at Doppelmayr, "and many machine tool manufacturers have had a hard time trying."

The correct speed for

the correct part

Project Manager Nicolay Schnitzer went hunting for an interlinked system to replace two machines from the existing fleet of machinery and satisfy rising capacity requirements. Essentially, there were several manufacturers in the running getting the component to determine the best alternative in concept and in a time study. "And this despite that fact that our attitude and history is relatively traditional," assures Doppelmayr Production Division Manager Karl-Heinz Zündel during talks, "and we didn't really want to use a new brand in production." Still, the fundamental questions remained, such as 'who provides what?', 'who has the proper spindle?', 'whose machine has the suitable dynamics?', and 'who can provide a pallet changer for the system?'.

And the results of the time study were unambiguous. Even though almost every provider was able to best the specified machining time for the reference part used to make the decision, the G750 universal machining center from GROB was by far the most dynamic. It could reduce the part machining time by 45 %.

The G750 with convincing

arguments

"With a second-generation G550 universal machining center in use, we had already been impressed with GROB technology," admits Nicolay Schnitzer. The table's kinematics, combined with the horizontal spindle, lets us get the pallets so clean after machining via a simple rinse and swivel cycle that virtually no remaining chips can be found on the unit, the pallet or the part. This reduces coolant carryover to a minimum. The savings from the simplified cleaning process are enormous. This may not be a big deal for one single pallet, but when 80 finished pallets are in the system after a weekend and each pallet only takes ten minutes to clean until retooling can be carried out, those are big savings in sum.

Nicolay Schnitzer, Doppelmayr Project Manager; Dominik Sohler, Doppelmayr Application Engineer; Dietmar Hagspiel, Alfleth GmbH Representative for GROB in Austria; Christoph Demmeler, GROB Regional Sales Manager (from left to right)

One more very important reason for Doppelmayr was the fact that the G750 required the least space of all machines presented. For the first part, the machine is equipped with a builtin coolant tank, a chip conveyor and a paper band filter that aid in keeping installation times short and the installation space very compact. Secondly, the machine can be loaded directly in the work area. This makes an additional pallet changer on the machine unnecessary, which in turn translates to a smaller installation space. The unique G-module concept lets Doppelmayr implement multiple clamping setups requiring a large swivel range of the rotary axis into a negative range, which could not have been done on other machines. "This fact offered us new possibilities necessitating a re-think of the clamping options and the unit layout," Schnitzer recalls. Another Doppelmayr motive for the G750 is that it can be loaded from the top, giving it the ability to continue operation as a stand-alone machine despite the automation system in the event of a robot failure.

All in all, the specific advantages of the GROB G750 universal machining center were clear. The most impressive features were and are:

high stability (this is important due to the machining difficulty posed by the material)

dynamic kinematics and the corresponding reference part machining time reduction of over 40 %

significantly reduced conversion and reclamping time (due to the large manual cleaning workload reduction)

the option for direct loading with no pallet changer

Pallet storage system and

central tool magazine

Increasing efficiency and high productivity through automation are important questions in production at Doppelmayr as well. One of the definitive requirements for Doppelmayr due to the given structural conditions was therefore: Making space for around 870 tools in an external pallet storage system with up to 120 pallets and a central tool magazine. Two decisive points relatively easily solved with the G750, as the GROB machine can be installed in front of the line and can automate without a pallet changer. This not only saves money on a pallet changer, but keeps proper access to the work area unchanged, an important factor when working in new parts.

On the subject of the central tool magazine, the primary concern was cost-effectiveness. Each of the four G750 universal machining centers has a tool changer with 60 pockets, but no additional external tool storage system. "An additional tool storage system with 200 tools on each machine would not have been possible in terms of spatial requirements," said Schnitzer.

The feature to point out of this system is thus the combination of a central tool storage system that can hold 870 tools and a robot for transport of the tools. As each machine also has its own tool magazine with 60 tools, approximately 1,110 tools can be accessed in total. A system of gantries transports the tools from the central storage system to the respective machine as required.

The central tool magazine with 870 HSK-A100 tools provides maximum flexibility for the complete system, as every part can be machined in any machine. The robot is additionally equipped with a back pouch for even faster loading / unloading of tools.

"Dynamic machines with a good concept and reliable service convinced us. Coolant and chip carryover is negligible in our interlinked system thanks to horizontal spindles and the swiveling tables. The linking with the system from Fastem gives us maximum flexibility. In the end, this concept was also the solution that saved us the most space for getting the most out of every square meter."

Karl-Heinz Zündel

Production and Logistics

Division Manager

"With the four interlinked G750 units, we achieve maximum cost efficiency by reducing machining times on the reference part by about 45 percent. The system operators are certainly also very glad that the parts and clamping fixtures come out of the system in clean condition. The complete system with its 120 pallet spaces and the central tool magazine gives the customer maximum flexibility due to machining for every part being possible on the next available machine. The perfect layout is also a very positive side-effect!"

Dietmar Hagspiel

GROB Sales, West Austria

Doppelmayr Group

The Doppelmayr Group represents quality, technological and market leadership in ropeway engineering for passenger and material transport, as well as high-tech intralogistics solutions.

3,403 employees worldwide

€ 872 million sales (GJ 19 / 20)

Located in Wolfurt / Austria

15,100 systems from Doppelmayr / Garaventa world-wide

50 countries worldwide have a subsidiary or a representative of the company group

96 countries Doppelmayr / Garaventa ropeways can be found in